I thought I’ll start a category talking about motorcycle maintenance. Starting off with understanding the engine design and basic theory.

The engine is the heart of your motorcycle. The engine changes energy into motion. In our case the energy is derived from controlled burning of fuel inside of an engine.

Internal combustion engine comes in variety of design depending on the type it can be four-stroke or two-stroke type. (There has some companies that tried a rotary engine -wankel which is outside the scope here).

All piston-powered internal combustion engine share a few fundamental characteristics. It doesn’t matter if it is tiny or huge, the basic principle remain the same.

Get the fuel into the engine that allows it to be burned, then some way of using that burning fuel to perform some useful work, then after fuel is converted to energy, some means of exhausting the remains.

Two-stroke engine is the first we will look at.

Two-stroke Basics

The engine derives its name from the fact that only two strokes of the piston (1 revolution of the crankshaft) are needed to complete the intake, compression, exhaust and power cycle.

There are some performance advantage that two-stroke enjoys over four-stroke, which is why it is primarily used in bikes requiring very high power-to-weight ratio such as dirt bikes. While the two-stroke(strokers) is gradually being phased out of racing, in part because racing two-strokes are noisy and environmentally dirty.

Two-stroke engine employs fewer moving parts and is inexpensive to design and build for utilitarian purposes, it dominates the moped and commuter bike market.

There are two principal difference between two and four-stroke engines.

- Basic two-stroke has no camshafts or valves : the fuel/air mix flows into the cylinder through small ports/holes.

- The way the engine is lubricated :

- lubricated by one or two methods

- oil is mixed directly to the fuel

- injected by pumps into the fuel as it leaves the carburetor or by some other system.

- because oil is heavier than fuel, it drops out of the mix and coats the bearings and piston skirt which lubricates them.

- much of the oil is burned and the remains exits the exhaust pipe in its natural state, emissions are a big problem that is why it is called dirty

- lubricated by one or two methods

Piston-Port Two-Stroke Engines

The most basic form of two-stroke design uses piston-port induction. In this design the fuel/air is drawn in the crankcase by the motion of the piston, passed to the combustion chamber through transfer ports, and then exhausted after combustion under the power of its own expansion.

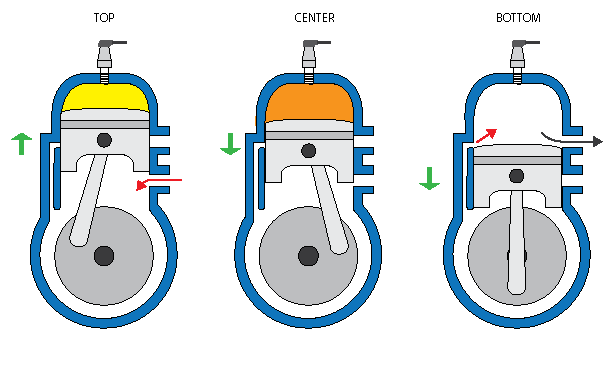

TOP – As the piston moves up from bottom dead center, a partial vacuum is produced in the crankcase. As it is moving forward its skirts clears the intake port, allowing fresh fuel/air into the crankcase, as piston moves further up it seals off the exhaust port and starts to compress the mixture in the combustion chamber.

CENTER – as piston nears top dead center, a spark occurs in the plug gap, igniting the compressed fuel mixture. The expanding gases pushes the piston down creating energy. As it goes down it seals the intake port and compresses the fuel/air in the crankcase.

BOTTOM – as piston moves pass the exhaust port, exhaust gases flows out. As it continuous down it exposes the transport port which releases the flow of the fuel/air into the compression chamber drawn from the compressed mixture in the crankcase chamber. After piston reaches bottom dead center, it starts upward again and as the piston passes the exhaust port, it seals it off, and the process repeats.

Read Valves and Rotary Valves

More sophisticated two-strokes are fitted with reed or rotary valves. The basic problem with piston-port engine is that the as the piston moves down, the crankcase pressure soon exceeds the atmosphere. When pressure is higher in the crankcase, the fuel mix will reverse direction and flow backwards out of the carburetor.

To prevent backflow a reed valve can be placed in the inlet tract. These are thin strips of metal that acts a one-way valve between intake and carburetor. When crankcase pressure is higher than atmospheric pressure, the valve closes.

In rotary-valve aka disk-valve two strokes, a partially cut-away disk rotates, opening and closing the intake port. The disk is typically attached to the crankshaft and is timed to open on the upward stroke of the piston so that opening in the disk allows fuel/air mixture enter the crankcase chamber. On downward stroke of the piston the disk closes preventing backflow.

Power Valves

Two-stroke performance big leap is the power valves. It is a moveable restriction placed in the exhaust port. A small electric motor similar to computer disc drive may control the power valve, though other versions are mechanically controlled.

In essence, large exhaust port is good for top-end power while small port enhances mid-range and low-speed running. The power valve is shaped like an eyelid. The control mechanism raises or lowers the eyelid depending on engine rpm.

In summary

Internal combustion engine fundamental characteristics is to burn fuel/air which creates an explosion that creates an expansion producing energy, using that energy into something useful and finally an exhaust method to discard the remains of what was burned.

Two-stroke engine only requires one cycle of the crankcase which covers intake, compression, power and exhaust.

There are different valves and mechanism to prevent backflow from the crankcase to the inlet valve. Power valve is used for performance by controlling the exhaust port depending on engine rpm.